About Our Steel

Pi Tape Texas, LLC offers a variety of steel and finish options designed to compliment every application. The following (listed below) are benefits to consider prior to making your purchase.

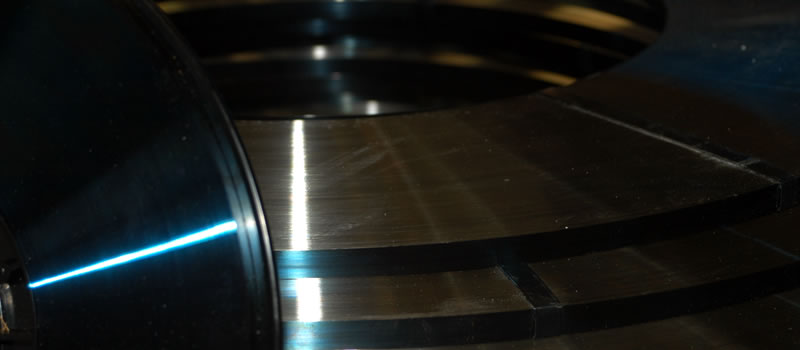

- 1095 Spring Steel is unquestionably the finest steel available for precision diameter tapes where thermal expansion and minimum stretch under normal operating tension ranges are a primary consideration. Pi Tape Texas, LLC has received spring steel tapes for recalibration service which were manufactured over 50 years ago and are still within our tolerance of 0.001". A light film coating of LPS3 oil is the only maintenance needed for these incredibly accurate instruments.

- Our 716 Stainless Steel, a specialty steel manufactured by Uddeholm, is utilized in more corrosive environments. Although stainless steel is a softer material with similar thermal expansion qualities as spring steel, it is used effectively in a multitude of industrial applications.

- Our Blue Easy to Read utilizes 1095 spring steel and is an extremely durable instrument, often utilized in low light environments or highly reflective conditions.

Physical Properties of Steel - Pi Tape Texas, LLC

| |

1095 Spring Steel |

716 Stainless Steel |

| Coefficient of Expansion

per inch per degree F. |

.0000065 |

.0000062 |

| Elongation % in inches |

7-10% |

7-12% |

| Hardness |

51 RC |

49-53 RC |

| Tensile Strength PSI |

259,600 |

248,000-277,000 |

| Yield Strength PSI |

235,690 |

210,000 |

The Relevant Criteria Regarding Thermal Qualities of Steel (Comparing coefficient of thermal expansion)

| |

Our spring steel: |

Other materials on the market: |

|

| |

.0000065” |

.0000092” |

Difference |

| 24” with 5ºf temp variable |

.0007” |

.0011” |

.0004” |

| 24” with 20ºf temp variable |

.0030” |

.0044” |

.0014” |

| 48” with 5ºf temp variable |

.0015” |

.0022” |

.0007” |

| 48” with 20ºf temp variable |

.0060” |

.0088” |

.0028” |